Proper Maintenance of Explosion Hazard Areas – A Cornerstone of Industrial Safety

Proper maintenance of explosion hazard areas is a cornerstone of industrial safety. Negligent maintenance can lead to serious accidents and production interruptions, highlighting the critical importance of systematic procedures and continuous monitoring. In Finland, the Safety and Chemicals Agency (Tukes) actively supervises the maintenance of these areas as part of chemical and electrical safety oversight.

Explosion Hazard Areas and Their Risks

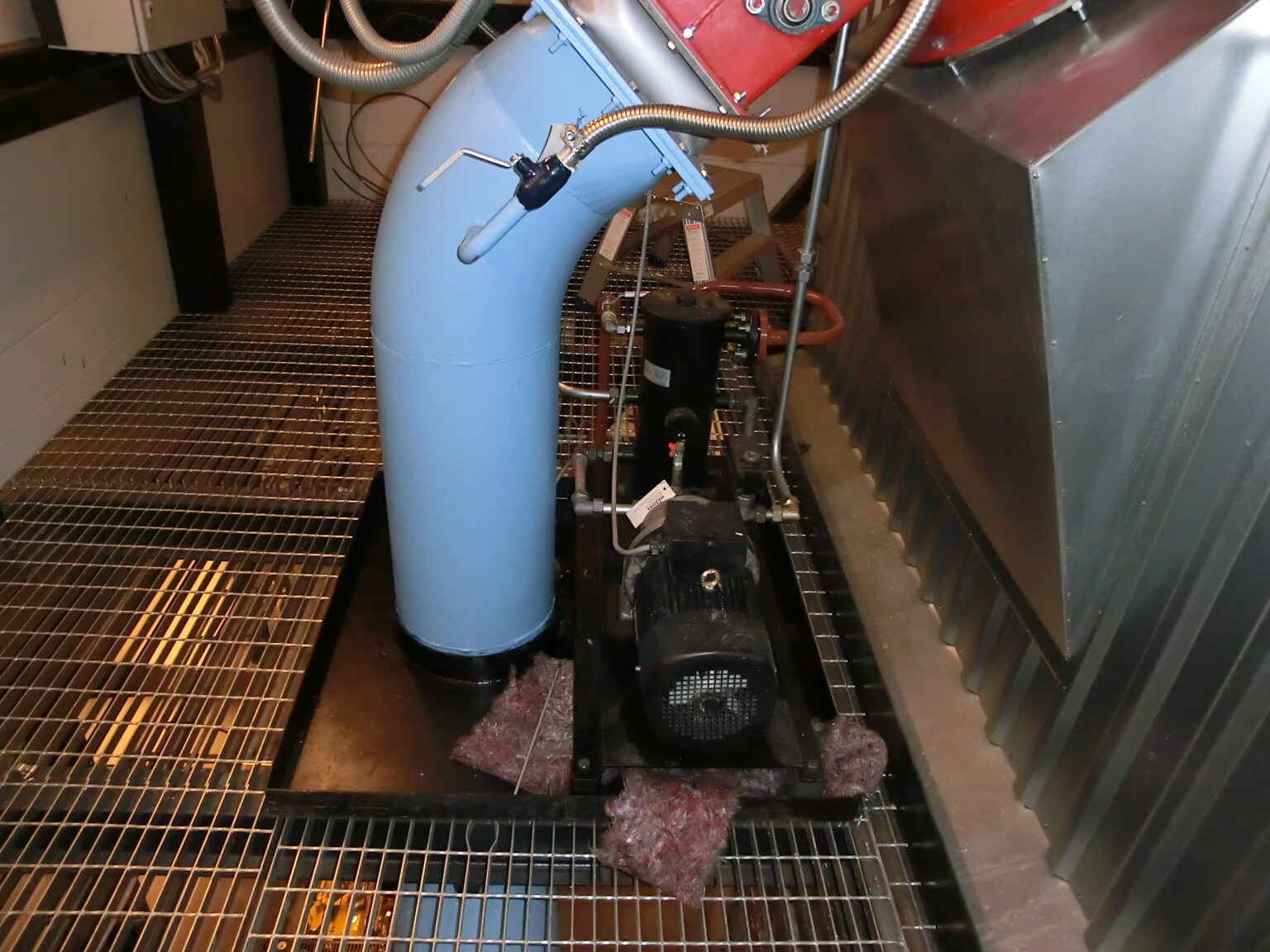

Explosion hazard areas occur when flammable gases, mists, vapors, or dusts mix with air. In such environments, electrical installations and equipment must not act as ignition sources. Tukes monitors the safety of ATEX zones, and previous inspections have revealed shortcomings such as outdated classifications, inadequate maintenance systems, and issues in electrical inspections. A follow-up project underway in spring 2025 aims to map out companies’ maintenance practices in ATEX zones and for related equipment. The results will be published in the fall.

Legislation and Responsibility in Finland

Finnish legislation, such as the Occupational Safety and Health Act (738/2002) and the Electrical Safety Act (1135/2016), sets strict requirements for managing explosion hazard areas. Employers are obligated to identify explosion risks and assess their impact on employees’ health and safety. Every workplace that stores or handles flammable liquids, gases, or dusts must have an explosion protection document. This document must be kept up to date and reviewed whenever changes occur in operations, facilities, raw materials, or equipment.

The ATEX regulations are based on the EU Directive 1999/92/EC, which outlines minimum requirements for improving the health and safety of workers potentially at risk from explosive atmospheres. Standards such as SFS EN 60079-14 define specific requirements for electrical installations in explosive atmospheres. Equipment suppliers must provide sufficient information for the safe installation, use, and maintenance of devices. In Finland, electrical devices in explosion hazard areas must undergo periodic inspection every 10 years.

Key Measures and Best Practices

To ensure explosion protection, employers must implement several measures. We have assisted multiple clients in managing challenging environments:

Hazard Identification and Risk Assessment

-

Identify all potential explosion hazard zones and conduct thorough risk assessments.

Risk Management

-

Risk control measures must follow this priority order:

-

Prevent the formation of explosive atmospheres,

-

Avoid ignition of explosive atmospheres,

-

Mitigate the harmful effects of explosions.

-

Explosion Protection Document

-

The facility operator must create and maintain a comprehensive explosion protection document, which includes technical and organizational preventive and protective measures as well as hazardous area classification.

Training

-

Ensure all individuals working in, designing, installing, or supervising explosion hazard areas have appropriate and up-to-date training.

Equipment Selection and Maintenance

-

Use only ATEX-certified equipment designed for safe use in explosive environments. Regular servicing and maintenance are essential to ensure safe operation.

Prioritization of Measures

-

The primary goal is to prevent the formation of explosive atmospheres. If this is not possible, efforts must be made to prevent ignition sources and mitigate the harmful effects of explosions.

Continuous Monitoring

-

The work environment, safety procedures, and the effectiveness of implemented measures must be continuously monitored.

Tarkes Expert Services

Tarkes Quality provides expert services related to ATEX compliance and explosion protection. Our services include ATEX consulting, training, drafting explosion protection documents, hazardous area classification, pressure impact assessments, risk assessments, and equipment inspections. Our cooperation with qualified third parties helps companies ensure compliance and enhance their safety practices.

Contact

Tarkes Quality Oy

Mikko Ketala

+358 44 066 6802